About Us

Ningbo S J Electronics Co., Ltd. was established in Year 2019, located in Ningbo Economic and Technological Development Zone in Beilun District, Ningbo, China. Our company focuses on the high-end integrated circuit packaging advanced materials. With the vision of "creating first-class core materials and improving human experience", we strives to become an internationally leader in core packaging materials, technologies and equipment for high-computing chips (CPU, GPU, 5G/6G, AI, Automotive etc.).

Many of our products are used in many fields

Solder is used for mechanical connection, electronic manufacturing, semiconductor device assembly, etc.

Alloying expertise for applications ranging from thermal management to thin film technology to fusible devices

Our Products

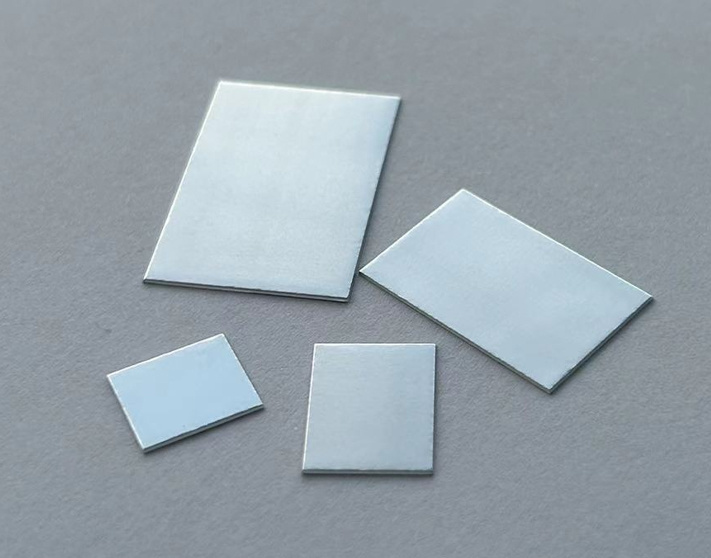

S J Electronics high precision Indium preform products are uniquely developed as thermal interface materials (TIM1) for CPU packages. Thermal conductivity is > 80 W/(m.k). During package assembly, in order to achieve the best interface thermal conductivity, a thin wetting metal layer is needed on the back side of the die to wet the Indium preform, and connect to I H S (Integrated Heat Spreader). At the same time, using appropriate flux to make sure Indium covering all of the die surface during reflow process without internal and interfaces voids to ensure most effective interface heat transfer.

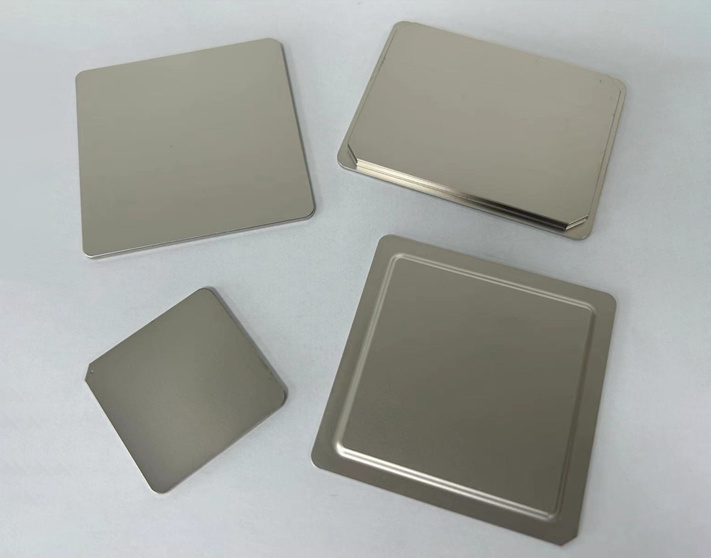

View DetailsIntergrated Heat Spreader (IHS)

S J Electronics offers high-end integrated head spreaders (IHS) with superior precision and quality. These precision-engineered, high-end integrated heat spreader are offered in 37.5 mm x 37.5 mm with nickel plated, or 72mm x 55mm, with nickel / gold plating on the surface. Our IHS can achieve Thermal conductivity greater than >400W/(m.k) with customization into lid-type, hat-type or stiffener ring.

View DetailsCore Competitiveness

01

Leading R & D capabilities for advanced materials applications

Solder/welding, thin film/interface/nanomaterials, metal forming and forming, packaging, thermodynamics, mechanical engineering, metallurgy, chemistry, electromigration, material analysis.

02

Quality Control

High volume manufacturing process and quality control.

Stable and consistent quality.

03

Design and manufacturing capability

Equipment Design and Manufacturing,

Control Software Design and Manufacturing,

Integrated automation,

Automatic Optical Inspection (AOI) set.

Careers

News